Comparing Oscillating Knife Cutting Machines vs. Laser Cutting: A Comprehensive Guide

- jinandirui

- Sep 29, 2023

- 3 min read

In the world of modern manufacturing and design, precision cutting is crucial. Two popular methods that have gained prominence are oscillating knife-cutting machines and laser cutting. Choosing the right tool for your needs is vital to ensure efficiency and quality. This comprehensive guide will investigate comparing oscillating knife-cutting machines versus laser cutting. Let's explore these technologies to help you make informed decisions about your projects.

Oscillating Knife Cutting Machines: The Basics

Oscillating knife-cutting machines, also known as CNC knife cutters, are versatile tools used for cutting various materials with precision. These machines utilize a rapidly oscillating blade to make intricate cuts in materials like foam, rubber, fabric, and even soft metals. When looking for a reliable Oscillating knife Cutting Machine supplier, it's essential to consider the capabilities of these machines.

Advantages of Oscillating Knife Cutting Machines

Versatility: Oscillating knife cutters can handle various materials, making them suitable for diverse applications.

Precision: The oscillating blade allows for intricate and precise cuts, perfect for detailed designs.

Cost-Efficiency: These machines are relatively affordable compared to some other cutting methods.

Disadvantages of Oscillating Knife Cutting Machines

Limited Thickness: They are not ideal for cutting very thick materials, as the oscillating blade may struggle.

Maintenance: Regular maintenance is required to keep the blade in optimal condition.

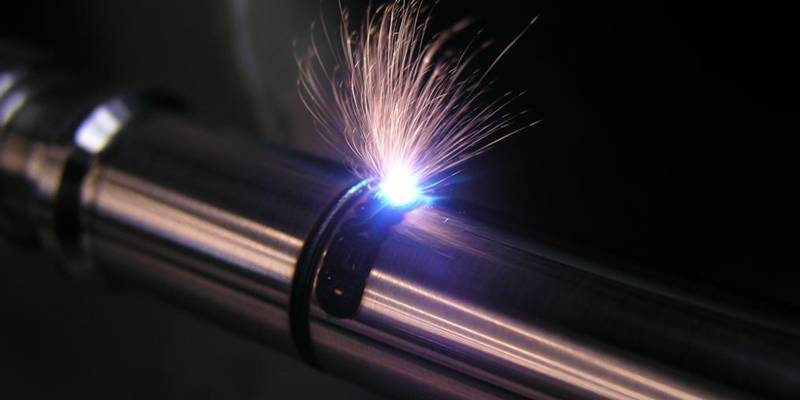

Laser Cutting: The Basics

On the other hand, a laser cutting machine employs a high-powered laser to cut through materials with extreme precision. It's widely used in industries like aerospace, automotive, and signage.

Advantages of Laser Cutting

Precision: Laser cutting offers unparalleled precision, making it suitable for intricate and delicate designs.

Speed: It is incredibly fast, which can be a significant advantage in mass production.

Clean Cuts: Laser cutting leaves clean, sealed edges with minimal material wastage.

Disadvantages of Laser Cutting

Material Limitations: Laser cutting is most effective on certain materials, such as metals and plastics, and may not work well on reflective or transparent materials.

Initial Cost: The high initial cost of laser cutting machines can be a barrier for some businesses.

Comparing Oscillating Knife Cutting Machines vs. Laser Cutting

When deciding between these two cutting methods, several factors come into play.

Material Type

Oscillating Knife Cutting Machines: Ideal for soft materials like fabric, foam, and rubber.

Laser Cutting: Best suited for hard materials like metals and plastics.

Precision

Oscillating Knife Cutting Machines: Offers precision but may not match the laser's accuracy.

Laser Cutting: Provides unmatched precision, making it perfect for intricate designs.

Speed

Oscillating Knife Cutting Machines: Generally slower compared to laser cutting.

Laser Cutting: Extremely fast, making it ideal for high-volume production.

Cost

Oscillating Knife Cutting Machines: More affordable in terms of initial investment.

Laser Cutting: High initial cost, but cost-effective for large-scale operations.

Maintenance

Oscillating Knife Cutting Machines: Requires regular blade maintenance.

Laser Cutting: Minimal maintenance is needed.

Conclusion

There is no one-size-fits-all answer in the ongoing debate of oscillating knife-cutting machines vs. laser cutting. The choice depends on your needs, materials, budget, and production volume. Oscillating knife-cutting machines are versatile and cost-effective for softer materials and smaller-scale projects, while laser cutting shines in precision and speed for industrial applications. Evaluate your requirements carefully to make the right decision for your business or creative endeavors.

FAQs

Q1: Can laser cutting be used for cutting fabrics?

Yes, laser cutting can be used for fabrics, but choosing the appropriate laser and settings is essential to prevent scorching or burning.

Q2: Are oscillating knife-cutting machines suitable for cutting metals?

While they can cut soft metals, oscillating knife-cutting machines are not the best for thick or hard metals.

Q3: What is the main advantage of laser cutting for industrial applications?

The primary advantage of laser cutting in industrial applications is its unmatched precision and speed, which can significantly increase production efficiency.

Q4: Do laser-cutting machines require a lot of power?

Yes, laser-cutting machines can be power-hungry, so it's important to consider energy costs in your operations.

Q5: Can oscillating knife-cutting machines be used for woodworking?

Oscillating knife-cutting machines can be used for woodworking, particularly for intricate designs and softer woods.

Comments