Why High-Quality Laser Marking Machines Are Worth the Investment

- jinandirui

- Dec 22, 2023

- 4 min read

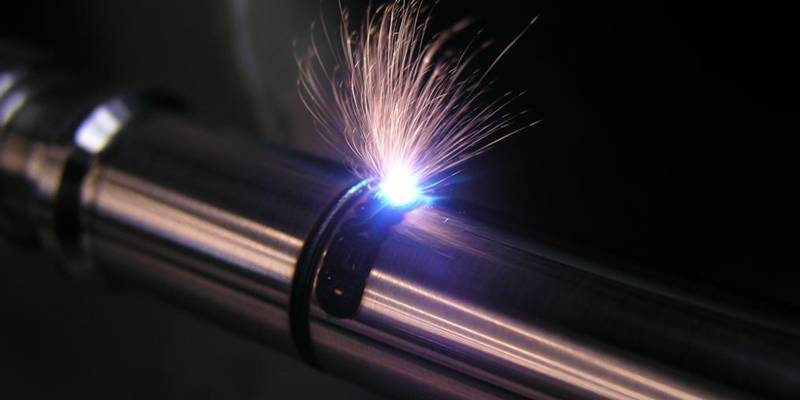

Laser marking has become an integral part of various industries, offering a precise and efficient way to mark materials. As businesses strive for accuracy and reliability, high-quality laser marking machines have emerged as indispensable tools. Let's delve into why investing in these advanced machines is a strategic move for any forward-thinking enterprise.

Benefits of High-Quality Laser Marking Machines

Precision and Accuracy

High-quality laser marking machines excel in providing unparalleled precision and accuracy, making them ideal for a variety of applications. Whether you are engraving serial numbers on delicate electronic components, marking expiration dates on pharmaceutical packaging, or exploring options for wholesale high-quality laser marking machines, these advanced devices guarantee that every detail is etched with utmost precision.

Versatility in Materials

One of the standout features of top-tier laser marking machines is their ability to mark a wide range of materials. From metals and plastics to ceramics, these machines showcase remarkable versatility, making them suitable for diverse applications across industries.

Durability of Markings

Investing in high-quality laser marking ensures that the markings endure the test of time. Unlike traditional marking methods that may fade or wear off, laser markings boast exceptional durability, maintaining their clarity and legibility even in challenging environmental conditions.

Applications Across Industries

Automotive Sector

In the automotive industry, laser marking plays a crucial role in labeling parts, ensuring traceability, and meeting regulatory requirements. High-quality laser markings withstand the rigors of the automotive environment, contributing to overall product reliability.

Electronics and Semiconductor Industry

Precision is paramount in the electronics sector, and high-quality laser marking machines deliver just that. From microchips to circuit boards, these machines create intricate and durable markings essential for product identification and quality control.

Medical Devices and Pharmaceuticals

In the medical field, where accuracy can be a matter of life and death, laser marking ensures that medical devices and pharmaceutical products are appropriately labeled and traceable. The non-contact nature of laser marking also contributes to maintaining product sterility.

Cost-Effectiveness in the Long Run

Reduced Maintenance Costs

While the initial investment in high-quality laser marking machines might seem substantial, the long-term benefits include significantly reduced maintenance costs. These machines are designed for durability and reliability, minimizing the need for frequent repairs or replacements.

Increased Efficiency and Productivity

The speed and efficiency of laser marking machines contribute to increased overall productivity. Swift and accurate markings translate to streamlined production processes, allowing businesses to meet demands with ease.

Technology Behind High-Quality Laser Marking

Different Types of Laser Marking Technologies

High-quality laser marking machines leverage various technologies such as Fiber, CO2, and UV lasers. Each technology offers unique advantages, catering to specific material and application requirements.

How They Ensure High-Quality Results

The technology behind these machines ensures that the laser beam interacts with the material precisely, creating high-resolution markings. The controlled energy delivery prevents damage to the material while achieving the desired marking depth.

Choosing the Right Laser Marking Machine

Factors to Consider

Selecting the right laser marking machine involves considering factors such as the type of material, required marking speed, and the complexity of the design. Understanding these aspects helps businesses choose a machine that aligns with their specific needs.

Customization Options

Top-quality laser marking machines offer customization options, allowing businesses to tailor the marking process to their unique requirements. This flexibility ensures that the machine adapts to different materials and applications seamlessly.

Future Trends in Laser Marking Technology

Emerging Technologies

The landscape of laser marking continues to evolve, with emerging technologies promising even more advanced features. From faster marking speeds to increased energy efficiency, businesses can anticipate continuous improvements in laser marking technology.

Potential Advancements and Innovations

As technology progresses, laser marking machines may incorporate innovations such as artificial intelligence for enhanced automation and smart features. These advancements aim to further elevate the precision and capabilities of laser marking in industrial applications.

Addressing Concerns About Laser Marking

Safety Measures

Safety is a paramount concern in any industrial setting. High-quality laser marking machines come equipped with safety features, including enclosures and interlocks, ensuring a secure working environment for operators.

Environmental Impact

To address environmental concerns, modern laser marking machines are designed with energy efficiency in mind. The minimal waste generated during the marking process contributes to a more sustainable and eco-friendly manufacturing approach.

Comparing Laser Marking with Other Marking

Technologies

Advantages Over Traditional Methods

Compared to traditional marking methods, laser marking offers distinct advantages, including faster processing times, greater precision, and the ability to mark a wider range of materials. These benefits position laser marking as a superior choice for modern manufacturing needs.

Comparison with Inkjet and Dot Peen Marking

Inkjet and dot peen marking are alternative technologies with their own set of strengths and limitations. A comparative analysis highlights why high-quality laser marking machines often outperform these alternatives in terms of efficiency, durability, and overall marking quality.

Investment Return and ROI

Calculating Return on Investment

While the initial investment in high-quality laser marking machines may seem significant, businesses can calculate the return on investment by factoring in increased productivity, reduced errors, and minimized maintenance costs. The long-term benefits often far outweigh the upfront expenses.

Long-Term Benefits for Businesses

The strategic investment in high-quality laser marking machines positions businesses for long-term success. Beyond immediate gains in efficiency, these machines contribute to improved product quality, enhanced brand reputation, and compliance with industry standards.

Challenges and Solutions

Common Challenges in Laser Marking

Despite their advantages, laser marking machines may encounter challenges such as material inconsistency or complex designs. Understanding these challenges is the first step toward implementing effective solutions.

Strategies to Overcome Them

Addressing challenges involves implementing strategies such as optimizing machine settings, conducting regular maintenance, and providing adequate training to operators. Overcoming obstacles ensures a smooth and efficient laser marking process.

Industry Standards and Regulations

Compliance Requirements

Various industries have specific standards and regulations governing product marking. High-quality laser marking machines are designed to meet these requirements, ensuring that businesses remain compliant with industry standards and regulations.

Ensuring Adherence to Quality Standards

Maintaining consistent and high-quality markings is essential for compliance. Regular calibration, adherence to recommended settings, and periodic quality checks contribute to meeting and exceeding industry quality standards.

Conclusion

In conclusion, the investment in high-quality laser marking machines is a strategic move for businesses aiming for precision, efficiency, and long-term success. From their unmatched accuracy to the versatility in materials, these machines offer a myriad of benefits that transcend traditional marking methods.

As industries continue to evolve, embracing the advancements in laser marking technology becomes imperative. The future holds exciting possibilities with emerging technologies and innovations, ensuring that businesses stay at the forefront of efficiency and quality.

Comments