Laser Marking vs. Traditional Marking Methods: Pros and Cons

- jinandirui

- Nov 17, 2023

- 3 min read

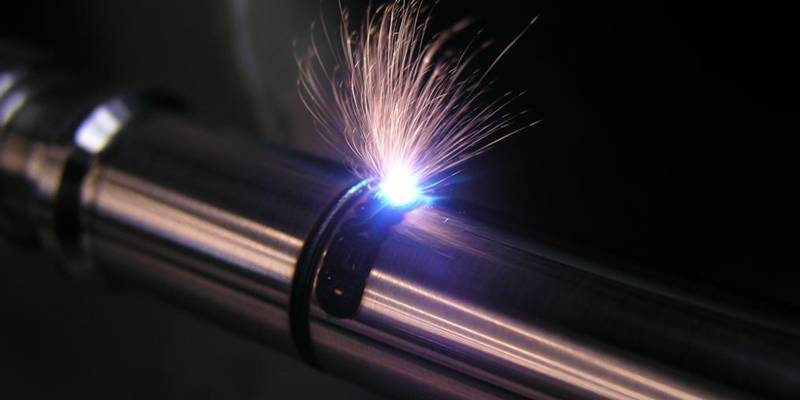

In the ever-evolving world of marking methods, the selection between Laser Marking and Traditional Marking Methods holds paramount importance for a multitude of industries. Grasping the advantages and disadvantages is fundamental for making well-informed decisions. Especially when seeking a wholesale high-quality laser marking machine, the distinction between these methodologies becomes critical for businesses aiming for precision and efficiency in their operations.

Advantages of Laser Marking

Precision and Accuracy

Laser Marking boasts unparalleled precision, ensuring intricate details with minimal margins of error. The laser beam's focus allows for micro-level markings, which is crucial in industries requiring exact specifications.

Speed and Efficiency

The speed at which laser marking operates is a game-changer. High-speed laser systems enhance efficiency, increasing productivity and reducing production times.

Versatility in Material

Unlike traditional methods limited by material constraints, laser marking adapts seamlessly to various surfaces, from metals to plastics. This versatility widens its applicability across diverse industries.

Disadvantages of Laser Marking

Initial Investment

One of the primary drawbacks is the initial investment required for laser marking systems. While cost-effective in the long run, the upfront expenses might be a barrier for some businesses.

Maintenance Costs

Though low maintenance compared to some traditional methods, Laser marking systems still incur maintenance costs. Regular check-ups and occasional repairs add to the overall operational expenses.

Limited Depth

Laser marking's depth capabilities may fall short for applications requiring deep engravings. In such cases, traditional methods like stamping might offer more suitable alternatives.

Applications in Industries

Automotive

The automotive industry benefits from laser marking's precision for part identification, ensuring traceability and quality control.

Aerospace

In aerospace, where lightweight materials are prevalent, laser marking provides a non-intrusive solution for labeling critical components.

Medical

Laser marking finds extensive use in medical devices, ensuring permanent and sterile markings for instruments and implants.

Traditional Marking Methods

Overview

Traditional methods like engraving, stamping, and dot peen have been the backbone of marking for centuries, offering reliability and familiarity.

Types

Explore the nuances of engraving, stamping, and other traditional methods, each with unique applications and characteristics.

Laser Marking Techniques

CO2 Laser Marking

Delve into the details of CO2 laser marking, understanding its applications and suitability for different materials.

Fiber Laser Marking

Explore the advantages of fiber laser marking, especially in industries requiring high precision on various materials.

YAG Laser Marking

Learn about the YAG laser marking technique, its strengths, and where it outperforms other methods.

Environmental Impact

Comparison of Environmental Footprints

Analyze the environmental impact of laser marking versus traditional methods, considering factors like emissions and resource usage.

Waste Generation

Explore how waste generation differs between laser marking and traditional methods, influencing sustainability practices.

Energy Consumption

Dive into the energy consumption patterns of both methods, crucial for industries striving for energy efficiency and reduced carbon footprints.

Safety Considerations

Eye and Skin Safety

Understand the safety protocols associated with laser marking to ensure protection against potential hazards to the eyes and skin.

Fume Extraction

Explore the importance of efficient fume extraction systems, a critical aspect of maintaining a safe working environment during laser marking.

Noise Levels

Consider the noise levels generated by laser marking machines and implement measures to mitigate their impact on the workplace.

FAQs

Laser marking is versatile but not universal. While suitable for various materials, certain compositions may not respond well to laser marking.

2. Can Traditional Marking methods achieve the same precision as Laser Marking?

Traditional methods can achieve precision but might lack the micro-level accuracy of laser marking. The choice depends on the specific requirements of the application.

3. What is the typical lifespan of a laser marking machine?

With proper maintenance, laser marking machines can have several years of lifespan, making them a reliable long-term investment.

4. How can one minimize the environmental impact of laser marking?

Implementing energy-efficient practices and proper waste management can significantly reduce the environmental impact of laser marking.

5. Are there any safety certifications for laser marking machines?

Yes, reputable laser marking machines often have safety certifications to ensure compliance with industry standards.

Conclusion

Summing up the pros and cons of Laser Marking vs. Traditional Marking Methods provides a holistic view for businesses seeking the most suitable marking solution. Understanding the nuances ensures an informed decision aligning with specific industry needs.

Comments