How to Choose the Right Laser Marking Machine for Your Business

- jinandirui

- Oct 31, 2023

- 4 min read

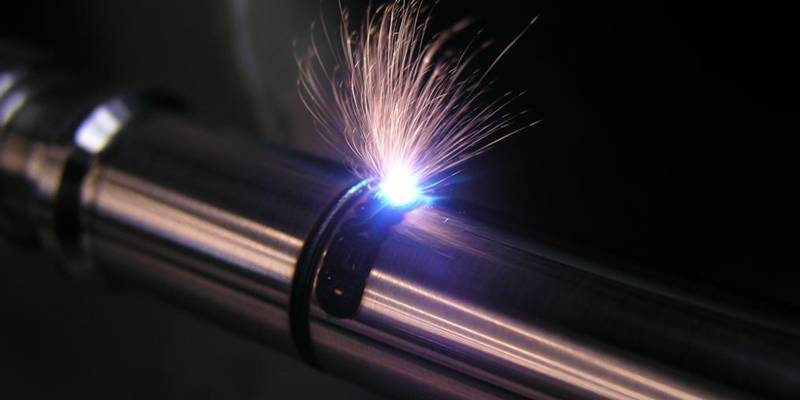

In today's fast-paced and competitive business world, efficient product identification and marking are vital for ensuring quality, traceability, and brand recognition. One technology that has revolutionized the field of product marking is laser marking. Laser marking machines offer precise and permanent marking solutions, making them a popular choice for various industries. However, choosing the right laser marking machine for your business can be a daunting task, given the multitude of options available in the market. In this comprehensive guide, we will explore the factors to consider when selecting the perfect laser marking machine to meet your business needs.

Understanding Laser Marking

Before delving into the factors that influence your choice, it's essential to understand what laser marking is and how it works. Laser marking is a process where a laser beam interacts with a material's surface, altering its properties to create a permanent mark. This process can be accomplished through different techniques, including engraving, annealing, foaming, and coloration. Understanding the basics of laser marking will help you make an informed decision, especially when considering options like a wholesale high quality laser marking machine for your specific needs.

Material Compatibility

The first and foremost consideration when choosing a laser marking machine is material compatibility. Different materials, such as metals, plastics, ceramics, and glass, require specific laser wavelengths and power levels for optimal marking. Therefore, it's crucial to select a machine that can effectively mark the materials used in your products. Ensure your chosen machine is compatible with various materials to accommodate future production changes.

Laser Type

Laser marking machines come in various types, the most common ones being CO2 lasers, fiber lasers, and UV lasers. Each laser type has unique advantages and is better suited for specific applications. CO2 lasers are ideal for marking organic materials, while fiber lasers are excellent for metal marking. UV lasers, on the other hand, are suitable for high-precision and high-contrast marking. Choose the laser type that aligns with your marking needs.

Marking Speed and Precision

The speed and precision of the laser marking machine play a crucial role in your production efficiency. Faster machines can mark more products in a shorter time, increasing productivity. Precision ensures that the markings are clear and accurate. The level of precision and speed required depends on your specific industry and production demands. Be sure to find a balance that meets your requirements without compromising quality.

Marking Depth and Quality

The depth and quality of the marks are significant factors, especially when dealing with parts or products that undergo wear and tear. Some applications require deep engraving, while others need shallow, surface-level marks. The quality of the marks should also be high, ensuring readability and durability. Consider your industry's marking depth and quality requirements when choosing a laser marking machine.

Size and Portability

The size and portability of the laser marking machine are essential considerations, particularly if your production setup has space constraints or requires mobility. Compact and portable machines are suitable for small workshops or businesses moving the machines between different locations. Ensure that the machine's size fits your workspace and production layout.

Software and Connectivity

A user-friendly and feature-rich software interface is vital for efficient operation and customization of the marking process. Additionally, connectivity options, such as USB, Ethernet, and wireless, are crucial for integrating the machine into your production environment. Ensure the machine's software and connectivity options match your existing systems and requirements.

Maintenance and Support

Owning a laser marking machine comes with maintenance responsibilities. Regular servicing and maintenance are essential to keep the machine in optimal working condition. When choosing a machine, consider the availability of spare parts, technical support, and the manufacturer's reputation for after-sales service. A reliable support system can minimize downtime and ensure the longevity of your investment.

Budget

Budget constraints are a reality for most businesses. It's essential to find a laser marking machine that meets your requirements without exceeding your budget. Compare prices, features, and the long-term cost of ownership before deciding. Remember that a well-invested machine can lead to significant cost savings and increased productivity over time.

Compliance and Regulations

Different industries have specific regulations and standards for product marking. Ensure that the laser marking machine you choose complies with these regulations. Failure to meet these requirements can result in costly legal issues and product recalls.

Conclusion

Selecting the right laser marking machine for your business is a critical decision that can significantly impact your product quality, efficiency, and brand reputation. By considering factors such as material compatibility, laser type, marking speed, precision, depth, size, software, maintenance, budget, and compliance, you can make an informed choice that aligns with your business needs. Invest the time and effort to research and evaluate your options, and you'll find a laser marking machine that enhances your production process and helps you stand out in the market.

FAQs

1. What materials can be marked with a laser marking machine?

Laser marking machines can mark various materials, including metals, plastics, glass, and ceramics. The material choice depends on the type of laser machine and its settings.

2. How much does a laser marking machine cost?

The cost of a laser marking machine varies widely based on factors like type, size, and capabilities. Prices can range from a few thousand dollars to several tens of thousands.

3. Can I use a laser marking machine for high-speed production?

Yes, you can. Some laser marking machines are designed for high-speed production, making them suitable for industries with fast-paced production lines.

4. Are laser marking machines safe to use in my business?

Laser marking machines are safe when used correctly. They come with built-in safety features, and proper training is essential to ensure safe operation.

5. How can I find a reputable brand for laser marking machines?

Researching online, reading reviews, and seeking recommendations from industry experts can help you find reputable brands that offer quality laser marking machines.

Comments