How to use a vibrating knife-cutting machine to create custom products

- jinandirui

- Nov 10, 2023

- 3 min read

Vibrating knife-cutting machines are versatile tools that can create a wide range of custom products. They are particularly well-suited for cutting soft materials such as fabric, foam, and cardboard.

What is a vibrating knife-cutting machine?

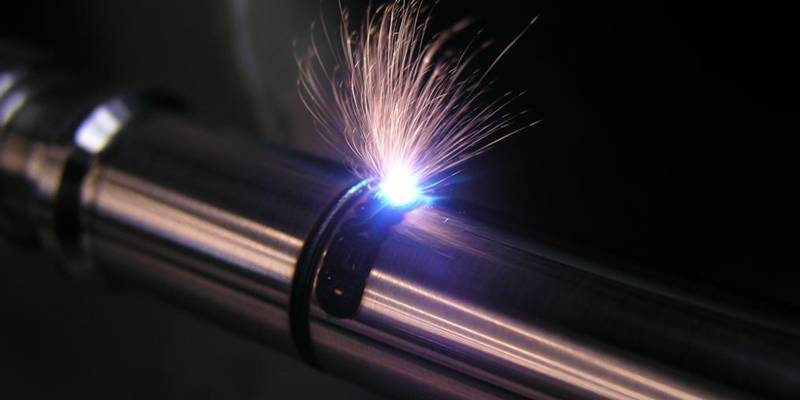

A vibrating knife-cutting machine uses a rapidly oscillating blade to cut through the material. The blade is typically made of a hard metal such as carbide or tungsten. The blade is mounted on a vibrating spindle, which causes it to oscillate back and forth at a high frequency.

The material to be cut is placed on a cutting table, and the vibrating knife is lowered onto it. The blade cuts through the material as it oscillates. The depth of the cut can be controlled by adjusting the height of the blade. Choosing a reliable Vibrating knife-cutting machine supplier ensures the efficiency and precision of this cutting-edge technology."

Benefits of using a vibrating knife-cutting machine

Vibrating knife-cutting machines offer several benefits, including:

Precision: Vibrating knife cutting machines can cut materials with high precision. This makes them ideal for creating custom products that require precise cuts.

Versatility: Vibrating knife cutting machines can cut various materials, including fabric, foam, cardboard, and other soft materials. This makes them a versatile tool for creating a wide range of custom products.

Speed: Vibrating knife-cutting machines can cut materials quickly and efficiently. This makes them ideal for high-volume production of custom products.

How to choose a vibrating knife-cutting machine

When choosing a vibrating knife-cutting machine, there are a few factors to consider, including:

The type of material you will be cutting: Vibrating knife cutting machines are designed to cut soft materials such as fabric, foam, and cardboard. If cutting harder materials, you must choose a machine specifically designed for that purpose.

The thickness of the material you will be cutting: Vibrating knife cutting machines can cut materials of varying thicknesses. However, each machine has its limitations. Make sure to choose a machine that can cut the thickness of the material you will be using.

The size of the products you will create: Vibrating knife cutting machines come in various sizes. Choose a machine large enough to cut the size of products you will be creating.

The features you need: Vibrating knife-cutting machines have various features, such as automatic material feed, dust collection systems, and computer control. Choose a machine that has the features you need for your specific application.

How to use a vibrating knife-cutting machine to create custom products

To create custom products with a vibrating knife-cutting machine, follow these steps:

Design your product: Use a computer-aided design (CAD) program to design your product. The CAD program will generate a cutting file that can be used to control the vibrating knife-cutting machine.

Prepare the material: Cut the material to the size of your product. If you are using fabric, make sure to iron the fabric before cutting it.

Load the material into the cutting machine: Place the material on the cutting table and align it with the cutting file.

Start the cutting process: Start the cutting process and allow the vibrating knife-cutting machine to cut through the material.

Remove the product from the cutting machine: Once the cutting process is complete, remove the product from the cutting machine.

Tips for creating custom products with a vibrating knife-cutting machine

Here are a few tips for creating custom products with a vibrating knife-cutting machine:

Use sharp blades: Sharp blades produce clean cuts and prevent material from fraying.

Use the correct cutting speed: The correct cutting speed will depend on the type of material you are cutting. If you cut too quickly, the blade may tear the material. If you cut too slowly, the blade may dull.

Use a lubricant: A lubricant can help to reduce friction and heat buildup. This will extend the life of the blade and produce smoother cuts.

Use a dust collection system: A dust collection system will help to remove dust and debris from the cutting area. This will improve the air quality in your workspace and make it easier to see the cutting area.

Test your cuts: Before you cut your final product, test your cuts on a scrap piece of material. This will help you to ensure that the cutting process is working properly and that you are happy with the results.

Conclusion

Vibrating knife-cutting machines are versatile tools that can create a wide range of custom products. Following the tips above, you can use a vibrating knife-cutting machine to create high-quality custom products that meet your needs.

Comments