Unlocking Possibilities: How Laser Cutting Machines Revolutionize Manufacturing

- jinandirui

- Jul 12, 2023

- 3 min read

Introduction

Staying ahead of the competition requires embracing cutting-edge technologies in the fast-paced manufacturing world. One such game-changer is the laser cutting machine. These advanced devices have revolutionized the manufacturing landscape, unlocking many once-unimaginable possibilities. With their precise cutting capabilities, enhanced efficiency, and versatility, laser cutting machines have become indispensable tools for various industries. In this article, we will explore how these machines have transformed manufacturing, empowering businesses to achieve new levels of success.

How Laser Cutting Machines Work

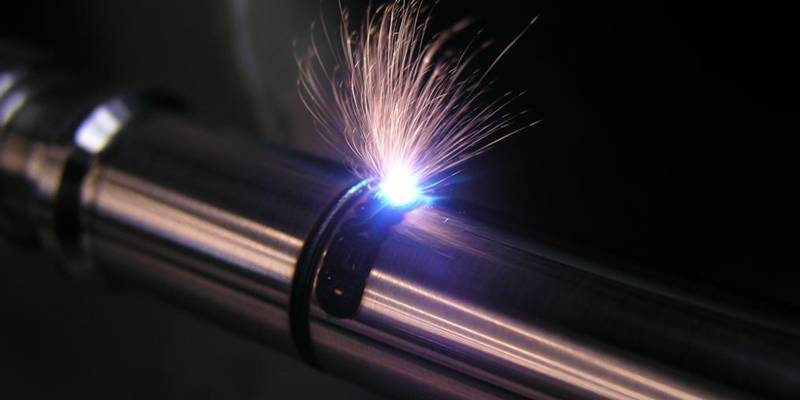

Before delving into the myriad benefits of laser cutting machines, it's essential to understand how they operate. At their core, laser cutting machines use a high-powered laser beam to cut through various materials with unparalleled accuracy. The laser beam is controlled by a computer program, which guides it along the desired cutting path, resulting in intricate and precise cuts.

Laser Technology: A Brief Overview

Laser cutting machines utilize concentrated beams of light generated through stimulated emission of radiation (LASER).

The laser beam is typically created by exciting a medium, such as carbon dioxide (CO2) or neodymium-doped yttrium aluminum garnet (Nd: YAG).

The Cutting Process

The laser beam focuses its energy onto the material's surface, melting or vaporizing it.

The high energy density of the laser beam allows for precise and efficient cutting through a wide range of materials, including metals, plastics, wood, fabric, and more.

Advantages of Laser Cutting Machines

The rise of laser cutting machines has revolutionized the manufacturing industry, offering numerous advantages over traditional cutting methods. Let's explore some of the key benefits:

Unmatched Precision

Laser cutting machines deliver exceptional precision, allowing for intricate and complex designs with tight tolerances.

The narrow laser beam produces minimal material waste and clean, burr-free cuts.

This precision enables manufacturers to create intricate shapes and patterns that were once extremely challenging or impossible.

Versatility Across Materials

Laser cutting machines can work with various materials, including metals, plastics, ceramics, composites, and fabrics.

The ability to handle different materials makes laser cutting machines highly versatile, accommodating diverse manufacturing needs.

Enhanced Efficiency and Speed

Laser cutting machines offer remarkable speed and efficiency compared to traditional cutting methods.

The automated process eliminates manual intervention, reducing production time and costs.

Moreover, the non-contact nature of laser cutting minimizes wear and tear, ensuring longevity and consistent performance.

Minimal Post-Processing

Laser cutting machines produce clean and precise cuts, minimizing the need for extensive post-processing.

The absence of burrs or rough edges reduces the time and effort required for finishing, saving time and resources.

Design Freedom and Customization

Laser cutting machines enable designers to unleash their creativity by offering unparalleled design freedom.

Intricate and complex designs can be easily achieved, fostering customization and personalization in manufacturing.

This flexibility empowers businesses to cater to unique customer demands and stay ahead in a competitive market.

FAQs About Laser Cutting Machines

Q1: What types of industries benefit from laser cutting machines?

A1: Laser cutting machines find applications across various industries, including automotive, aerospace, electronics, signage, jewelry, textiles, and more.

Q2: Are laser cutting machines safe to use?

A2: Laser cutting machines are designed with safety features, including enclosures and sensors, to protect operators from laser radiation. However, proper training and adherence to safety protocols are crucial.

Q3: Can laser cutting machines handle thick materials?

A3: Laser cutting machines can cut through a wide range of materials, including thick metals. However, the cutting thickness capacity may vary based on the machine and laser power.

Q4: Are laser cutting machines expensive? A4: The cost of laser cutting machines can vary depending on power, size, and additional features. However, they offer long-term cost savings through improved efficiency and reduced material wastage.

Conclusion

Laser cutting machines have emerged as transformative tools, revolutionizing the manufacturing industry in unprecedented ways. With their unparalleled precision, versatility across materials, enhanced efficiency, and design freedom, these machines have unlocked endless possibilities for businesses worldwide. From automotive and aerospace to textiles and jewelry, laser cutting machines drive innovation and empower manufacturers to stay ahead in a competitive market. As technology evolves, we can expect even more groundbreaking advancements in laser cutting, opening new horizons for manufacturing excellence. So, embrace the laser revolution and unlock a world of possibilities for your business.

Comments